Cutting 8mm PTFE/Silicone Septa

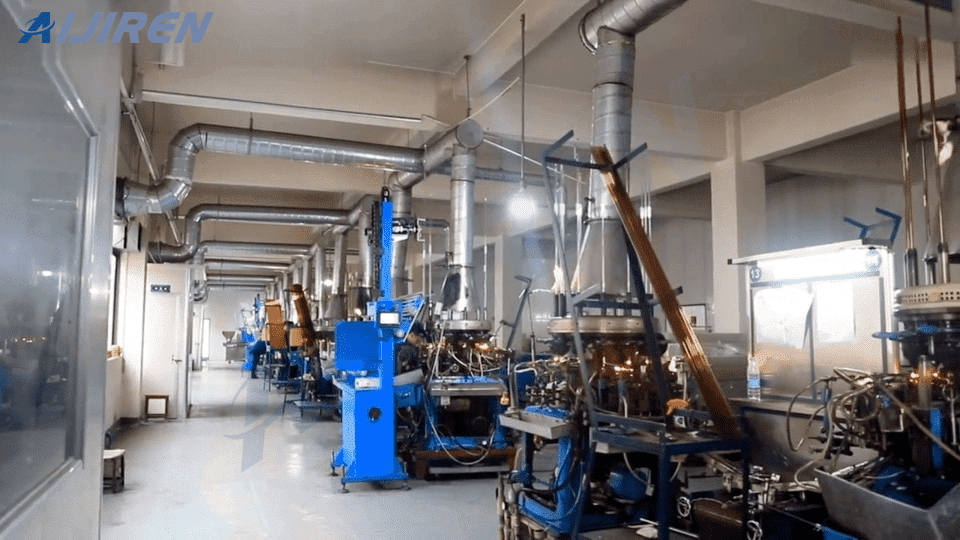

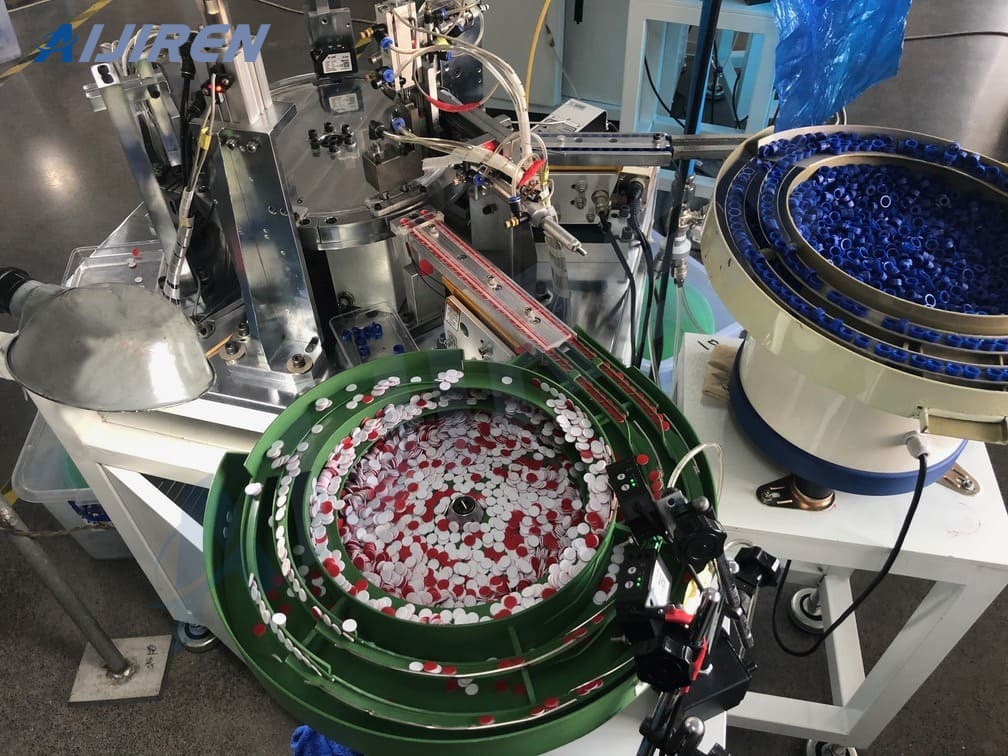

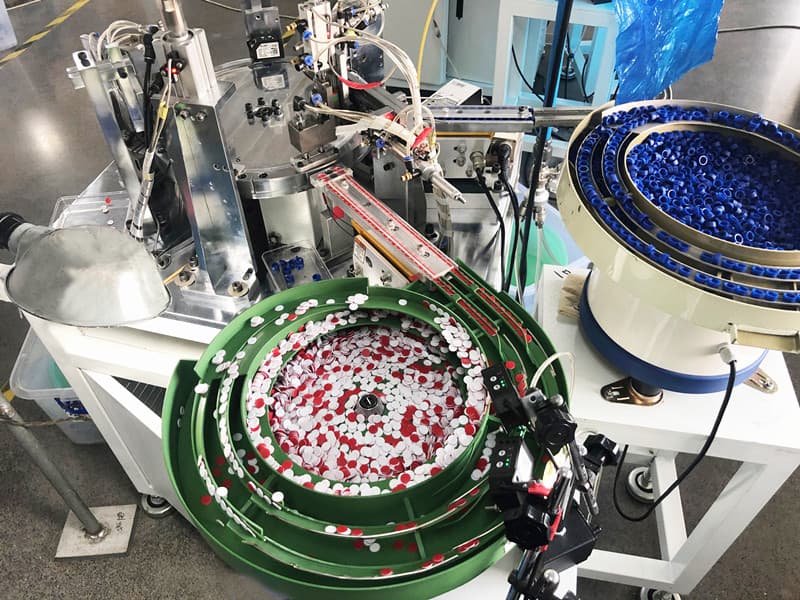

The Silicone/PTFE Septa produced by Aijiren uses high-quality raw materials and an exclusive compounding process. This process does not require any adhesives to compound Septa and Silicone to achieve no cracking, no falling off, and a perfect fit for autosampler vial and antosampler.

Contact US

Get Price

Share:

Previous:

9mm Screw Thread Closures

Content

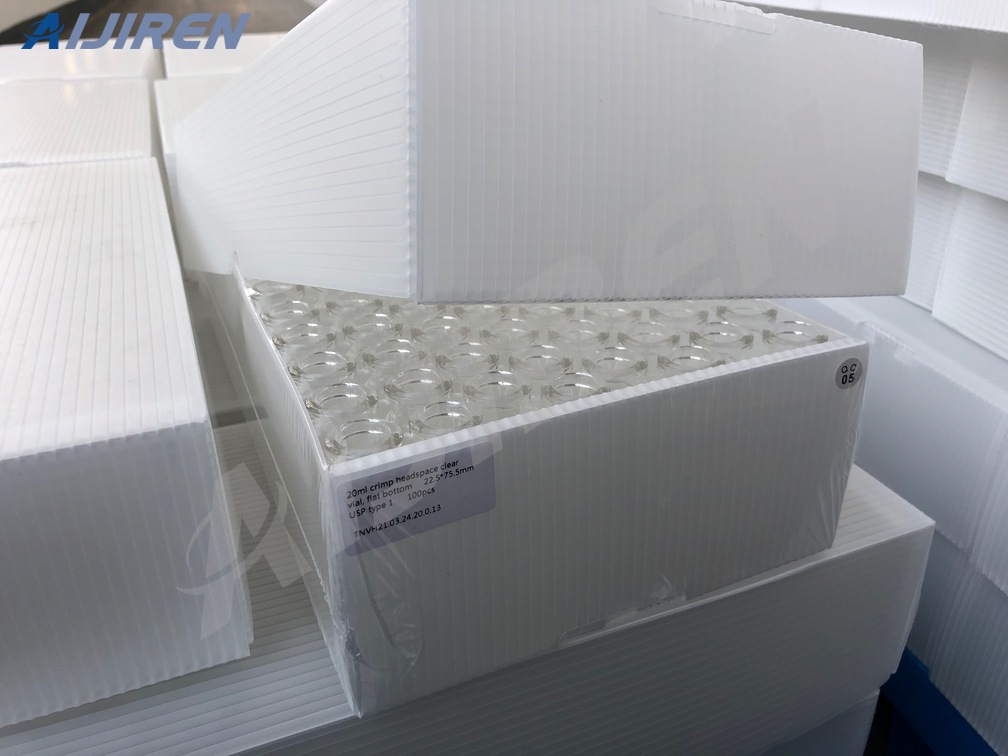

8mm PTFE/Silicone Septa is composited with high-quality PTFE and Silicone. The composite material after the composite is fixed on the machine, and workers are operated to cut the septa of the same size from the composite material. Because the machine uses laser cutting, it can complete a cutting in 1-2 seconds, so the composite material in the picture is cut in about one minute. This speed and efficiency are very fast, because only the parts to be cut need to be manually identified, and the cutting is completed mechanically. Cutting.

Aijiren’s 8mm PTFE/Silicone Septa has very significant features, such as high-quality raw materials. Both silicone and PTFE retain the characteristics of their respective materials. For example, silicone has a relatively stiff texture and is well suited for cutting. PTFE has a soft texture and is suitable for force-sealing between Vial and Cap, and inert PTFE is also suitable for storing samples, so the PTFE side of Septa often faces the inside of Vial.

Inquiry

More Workshop