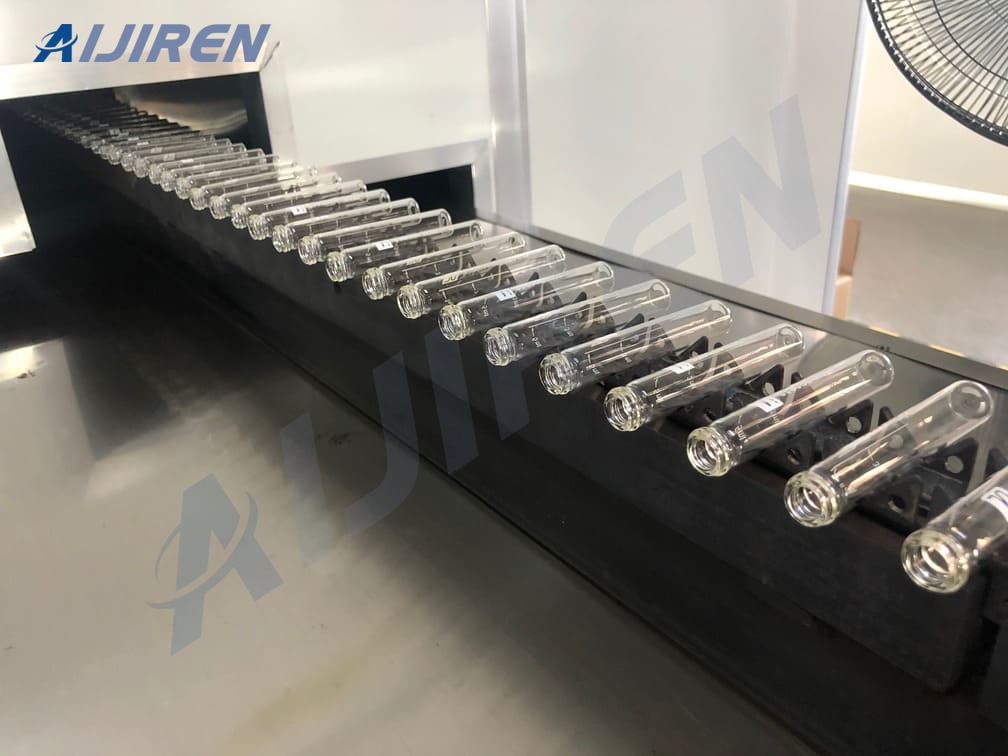

Screw Cap Mold Mading

When Aijiren produces screw top hplc vial, it will produce matching screw neck PP Cap, and different calibers and different types of vial require different Caps. In this case, new molds need to be polished for Cap production. The worker in the picture is here. For the grinding of the new mold, only the use of a suitable mold to install on an automated production machine can mass produce a suitable PP Screw Neck Cap.

Contact US

Get Price

Share:

Content

Among the most popular types of screw-neck bottle caps, several different types of calibers are very popular, such as 8mm, 9mm, 10mm and 13mm. Each different type of caliber means that a brand new mold is required. In terms of product development, in order to better seal and better meet customer needs, Aiji people will begin to develop new bottle cap production molds, such as the upgrade of the 9mm bottle cap side vertical line. This upgrade may seem inconspicuous, but it has made great progress in making it easier for customers to tighten bottle caps.

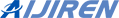

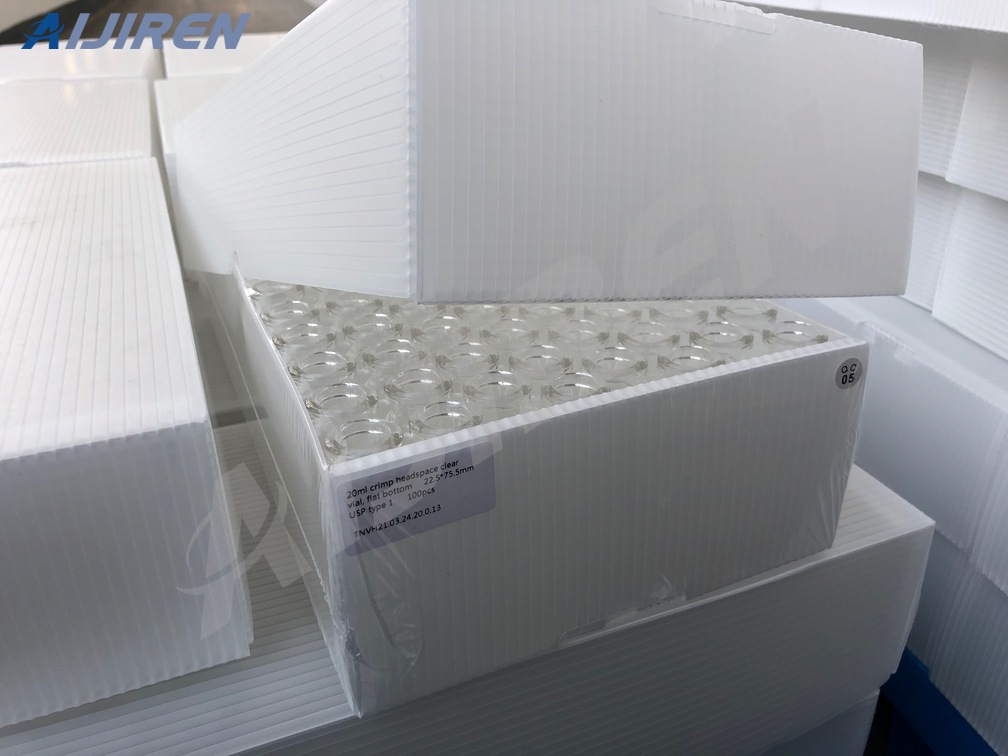

Aijiren’s factory production workshops are all dust-free workshops to ensure product quality while ensuring cleanliness. This has greatly improved Aijiren’s product quality. Aijiren’s strict self-requirements and control of product quality have made Aijiren’s Products have become popular and high-quality products, and Aijiren has also become the first choice for many customers when purchasing chromatography consumables.

Inquiry

More Workshop